FORSIS PANEL PC

PANEL PC - modular, flexible and sustainable

The term industrial PC covers such a range of different computer systems that it is difficult to keep track of them all. What they all have in common is, of course, that these devices are probably all used in an industrial environment. On closer inspection, the different variants quickly become clear.

We as FORSIS are specialized in the production of PANEL PCs.

The entire range of 19" computer slots, userless acquisition nodes, embedded box systems, etc. is not necessarily our task.

Our devices therefore always have a man-machine interface as a prerequisite. Our focus and specialization is the integration of input and output media in the PANEL PC. LCD for display and primarily touch screen for recording are always part of our PANEL PCs.

However, the PANEL PC must also be differentiated again. There are the so-called "built-in variants". In other words, PANEL PC designed for installation in control cabinets or wall openings, i.e. an additional protective housing is necessary.

Our understanding of the PANEL PC is a PC-based computer system with MMI with protection type housing.

PANEL PC in detail

What has to be considered? Of course - the control unit consists of a touch screen and LCD. She is the focus.

Equally important is the case. The possible uses of the PANEL PC are largely determined by the housing design. This also includes the expansion options, protective designs, etc.

The last point in the direction of integration into the network and IT structure of every company is the equipment of a PANEL PC.

The main areas of application for the PANEL PC are always where interaction plays a role.

Due to its protected housing, the PANEL PC is particularly suitable for use in production and process automation. This means that the interaction takes place in and around the production process.

This series is the answer to the question of how new, innovative programs can be used on Panel PCs in a harsh industrial environment. The need for information arises precisely in places where it is dusty and oily due to production. Thanks to the compact design of the Panel PC, this is also possible in places that are difficult to access. The space requirement is extremely small. There is no need to set up a PC workstation with a monitor, mouse and keyboard, as the slim panel PCs combine everything in one.

A solid and reliable panel PC needs a robust and compact housing that can withstand greater loads. All installed components must be protected against external influences and anchored accordingly. Vibration, dust, oils and flying sparks are unavoidable in the production environment, for example - coupled with the temperature fluctuations that occur, this is a major challenge for the hardware.

Further information on the protection class can be found here: Overview of protection classes

We offer panel PCs under the brand name PROFI. A distinction is made between the two touch screen technologies, analog resistive and capacitive.

Since 2007 they have been indispensable, smartphones with multi-touch! Since then we have long since gotten used to the intuitive multi-touch screens.

Quickly zoom into content with two fingers or scroll through a page with a swipe gesture. Many other useful functions even remain unused. This is due to the fact that the diverse possibilities of this technology are linked to the application and its functional support. In recent years, industrial applications have also discovered the advantages of multi-touch.

Thanks to the high level of acceptance among smartphone users, the usual operation can also be used for zooming in product drawings, for example. However, there are no limits to other possible applications - what is still missing is an industrial panel PC with multi-touch.

Due to the MULTITOUCH technology; But now there is also the opportunity in the process-related production environment to establish more interaction with the employee than before. Visualization on the one hand enables the LCD sizes up to 27". Combined with the possibility of using gesture control if the operating system supports it with the application.

FORSIS has made this challenge its core business and has successfully incorporated the experience of 25 years of company history into the design of the panel PCs across all products. Numerous industrial companies in almost all manufacturing sectors actively use Panel PCs from FORSIS.

The resistive Panel PC series of the PROFI series is designed for stationary use in an industrial environment. Particular attention was paid to the development of a device that can be used consistently for the different customer requirements.

From the simplest BDE feedback to complex visualization, the PROFI line offers everything you could wish for from a resistive panel PC.

MMI of the PANEL PC - PROFI series

- Display sizes from 10.4" to 27" offered

- Capacitive touchscreen - Capacitive touchscreen with water and palm rest detection

- Resistive touch screen - laminated glass effect

- Integration of RFID readers is possible, LEGIC© (advant), mifare© (DESFire) and hitag© are offered

- Protection class at least IP65 on the front, and can be customized on request

System data of the PANEL PC

- Protected and compact panel PC with integrated power supply unit

- Dust protection, IP65 on the front, IP52 on the connection side

- Operating temperature between 0° and +50°C

- Optionally upgradeable with WLAN and Bluetooth

- Extensive mounting options with VESA 100

Computer data of the PANEL PC

- Industrial boards, optionally equipped with an Intel Celeron, i3, i5 or i7 CPU

- Motherboards with UEFI BIOS and TMP 2.0

- 8 GB to a maximum of 32 GB

- min. 128 GB SSD mass storage, m.2 connection

- Various interfaces, such as 4xUSB, 1xHDMI, 2xGbeE and 2xRS232 interfaces

- Operating system according to MicroSoft CPU list WIN11 certification

- Alternatively IGEL Thin Client OS11

- Other interfaces and function keys available on request

Decades of experience have gone into our PROFI Panel PCs for stationary use. The basic modular principle meets your requirements without compromise - from the simplest BDE feedback to complex visualization with displays in various sizes and formats, with analog-resistive or capacitive touchscreens, with integrated readers and additional accessories.

- Ergonomic: with touch typing, automatic water and palm recognition

- Reader: RFID under the front glass, 1D/2D scanner on the underside of the housing (optional)

- Wireless: WLAN and Bluetooth (optional)

- Easy assembly according to VESA 100 standard

- Easy to maintain: Housing can be dismantled, connections are downwards, strain-relieved

3D views from the PROFI PANEL PC

Panel PC - PROFI MT - variants

With different display sizes up to 27", the Panel PC series PROFI MT offers a wide range of variants.

Your application can be visualized in the optimum resolution. The LCD with 16:9 format always offers Full-HD resolution.

LCD diagonals and resolution

15" / XGA

18.5" / FHD

21.5" / FHD

24" / FHD

27" / FHD

Thanks to the 16:9 format, the information on the panel PC is displayed in the same way as is usual in the office area - this eliminates the time-consuming redesign of the Views and the application can be taken over in the production area without much effort.

Industrial panel PC - LCD sizes

The resistive touch screen technology is unbeatable.

The resistive touch panel ensures that this panel PC can also be operated with gloves or styluses. In addition, the touch panel is absolutely insensitive to static charges and surface moisture. The perfect device for the demanding industrial environment!

LCD diagonals and resolution for the PANEL PCs with analog resistive touch screen.

10.4" / XGA

15" / XGA

17" / SXGA

19" / SXGA

21.5 / FHD

RFID reader integrated in the front of the panel PC

You want access authorization on the Panel PC to be via ID card or chip?

FORSIS offers you another optional and security-relevant possibility to equip the PROFI MT with an RFID - NFC card reader. The glass front runs continuously over the entire front of the device. Thus, the contactless RFID reader is integrated in the front.

We support the LEGIC© (advant), mifare© (DESFire) and hitag© reading processes in our Panel PCs. The RFID readers are programmed according to customer specifications. You are welcome to send us a test card so that we can ensure that the built-in reader on your BDE terminal is ready for use immediately upon commissioning.

Practical solutions - Handsfree

As an alternative or in addition to the external barcode reader, there is the option of permanently integrating a 2D barcode reader into the access protection of the resistive Panel PCs.

This is ideal for the resistive Panel PC of the PROFI series if there is a desire to read a barcode by hand. The data is passed on via USB/HID.

Front Design

An advantage of the FORSIS PANEL PC with resistive touch technology that should not be underestimated is that the front can be designed completely freely. In this example image you can see:

- RFID reader - The plastic panel on the front of the resistive panel PC offers the option of installing contactless reader systems. LEGIC© (advant), mifare© (DESFire) or hitag© are offered.

- Special function keys - Integrated function keys; A maximum of four buttons can be designed as desired, connection via keyboard controller via USB HID.

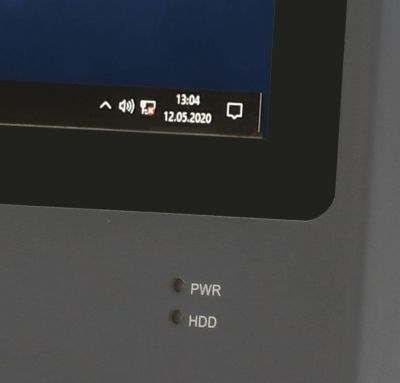

- Status display - two additional LEDs are available.

CPU variants

The Panel PCs of the PROFI series can be equipped with different CPUs.

Detailed information.

Attachment points

For easy attachment of the Panel PC, we offer a stand or wall bracket with tilt adjustment. On the back of the housing there are threaded studs with M5, which meet the VESA 100 standard and thus offer a wide range of installation options from table mounting to swivel technology. We would be happy to advise you on the selection of a suitable solution for installing your Panel PC - our large product range offers a suitable solution for even the most difficult task.

The ATX button on the side of the panel PC for switching on and off ensures convenient commissioning regardless of the chosen mounting option. You can also use the ATX button to assign other actions in the system settings of the operating system, such as "Change user".

Cable strain relief and access protection

All cable connections of the Panel PC are on the back and go down. To relieve the strain on the cables, four to six screw terminals are attached to a carrier, so the cables are bundled and the interface plugs are relieved.

To protect the plug connection, the entire connection side can optionally be closed with a protective hood, a so-called access protection. The cover is secured by two studs and two thumbscrews. Several versions of the cable outlet are offered, such as a version using RITTAL crimping technology or using classic PG screw connections.

"Wir beantworten gerne Ihre Fragen."

PCAP technique

The multi-touch front gives the Panel PC Multi-touch a visual upgrade and the front view is similar to commercially available tablet PCs. Thanks to the glass front, text and images appear more lively and richer in contrast, because there is no longer a film in front of it in comparison to the analogue resistive touchscreen. The built-in touch technology is installed flush in the housing, without any corners or edges, and gives the panel PC a timeless elegance. Nevertheless, the glass front of the Panel PC Multitouch with a high-security protective glass with a thickness of up to 2 mm is robust and more resistant to flying dust particles or sparks. Last but not least, the capacitive technology enables operation with up to 10 fingers.

Would you like to learn more about capacitive touch technology?

An important criterion in the industrial sector for the use of a capacitive touchscreen in the panel PC is operation with safety gloves. A lot has happened technologically in this area in recent years.

With each generation of multi-touch screens, the firmware of the touch controller has been further developed so that operation with safety gloves can now be guaranteed. The corresponding glove is individually matched to the touch screen.

Are you curious whether this also works with your gloves? We would be happy to provide you with a test device, just contact us.

ULV (UltraLowVoltage) CPU series from INTEL work under the hood of the PROFI series and in the other PANEL PC series of FORSIS.

These processor series are designed for fanless operation in closed systems. Due to the high degree of protection of our housing technology, this property is extremely important to us. Depending on the generation, the QUAD Core models from I5 are equipped with a CPU fan or passive heat sink. This is then supplemented by a case fan, which creates an air flow over the heat sink.

The case itself is always closed.

CPU variants of the INTEL series are used: SKYLAKE, WHISKEY LAKE and TIGER LAKE.

The different CPUs are suitable for all current operating systems.

The price/performance ratio is excellent and perfectly adequate for most client-server applications or web applications.

If you need more performance for your Panel PC, we would be happy to advise you.

The power supply unit is protected in the housing - this keeps the Panel PC free of attachments, which significantly simplifies the installation, because now all you have to do is plug it in and off you go!

All of the components we have selected are designed for continuous operation 24 hours a day, 7 days a week. It should be noted that the housing, CPU variants, interfaces, accessories and mounting options are identical for the PROFI and PROFI MT series. The only difference between the two Panel PC series is the touch panel technology.

One of the most important distinguishing features compared to many other panel PCs available on the market is that FORSIS relies on long-term availability. All selected components are available for many years. Depending on when you start a new generation of devices, we can supply the same or compatible spare parts for up to five years. This is sustainable and creates investment security, as is often desired by many companies, which is not only important in the event of service and after the warranty period.

Imagine you buy a few new Panel PCs and months later you re-order some of the same series. The Panel PCs that you have preconfigured can no longer be adopted one-to-one due to changed hardware technology. Many settings would have to be readjusted, which would mean effort and costs - and all because the manufacturer does not guarantee long-term availability.

Save yourself annoying touch-ups and eradicate the risks right from the start. Instead, rely on the professional Panel PC solution from FORSIS right from the start.